Pointers For Homeowner - Ceilings

Moulded Plaster Decorative Fittings

Finishes for ceilings are normally less compared with floors and

walls. However they should not be given less attention particularly

when it involves false ceilings. More problems are likely to surface

if they are not checked during installation.

The finishes for ceilings covered here are:-

- false ceilings

- skim coats

- moulded plaster decorative fittings

Painting work to ceilings follows that for walls which are given in Pointers For Homeowners - Walls.

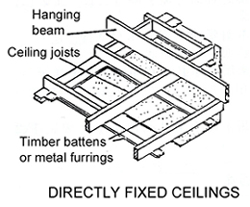

False ceilings are either directly fixed to their supports or suspended from them.

The timber joists with gypsum plasterboards as ceiling panels is the most common directly fixed ceiling. The ceiling boards and timber batten are fixed to:-

- horizontal timber joist under pitched roofs

- to the underside of sloping rafter beams or purlins

- above rafters or purlins, so that these could be seen from below

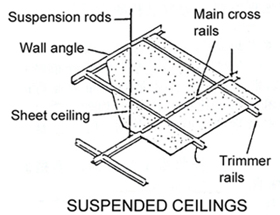

The ceiling panels are usually hung on:-

- T and L section metallic modular grid systems supported from structure above

- the flanges of I-section metallic structure members in proprietary combined roof and ceiling framing systems

Checks For Material Quality

-All timber elements like rafters and battens should be pressure treated with wood preservative.

-All metal fixings used should be corrosion-resistant.

-The ceiling panels made of gypsum plaster should have no cracks, holes or dents.

Checks For Quality Work

-For directly fixed ceilings, all fixings should be secured by scrim, a fabric material, to gypsum plaster ceilings panels.

-The plaster ceiling panels should be temporarily nailed in position first and then grout is used to attach them to the timber battens. Joints between plaster ceiling panels should also be grouted.

-After the grout has set and hardened, all temporary nailings and supports should be removed.

-All the joints and nail holes should be covered up and flushed.

-The surface of the plaster ceiling panels should be left to dry for at least a day before any painting to it is carried out.

-For suspended ceilings, all ceiling panels should either be dropped in, clipped in or on, screwed or bonded in place. Check that each panel is adequately secured and not loosely positioned.

Skim Coats

A skim coat is a paste of cement and small amount of hydrated lime. This is to be applied onto any rough concrete surface to create a level and smooth finished surface using steel trowels. Other more expensive premixed putty compound which gives a better finish may be used.

Checks For Material Quality

-In the mixing of the skim coating, quality hydrated lime, cement free of lumps and clean water should be used.

Checks For Quality Work

-Formwork joints should be grounded smooth and the concrete surfaces should be wetted prior to application.

-The thickness of the slurry coating should not be more than 1mm thick to avoid cracking.

-There should be no obvious brush marks.

-No poor bonding or hollowness should exist when the coated surface is tapped by knocking over coated surface with one's fingers.

-Surface unevenness should not exceed 10mm in 3m length of ceiling surface in any direction.

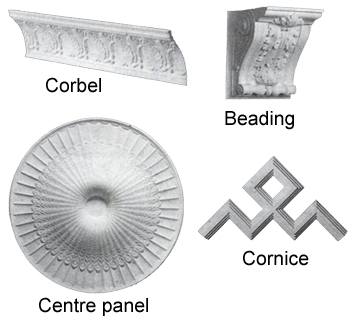

Moulded Plaster Decorative Fittings

These moulded fittings are made of plaster materials and are

installed onto the ceilings for decorative purpose. They include

cornices, corbels, centre panels and beadings. They come in

standard dimensions and patterns. Cornices are installed at the

ceiling-wall junction. Corbels are installed usually below the

beams and at the edge of the wall and ceiling junction. Centre

panels and beadings are installed in the centre of the ceilings.

Fig.2 The various moulded plaster fittings.

Checks For Material Quality

-They should be from the same stock and be of matching pattern.

-Bad and visible cracks, except hairline cracks should not be present.

-They should not be stained with any foreign substances.

-There should not be any algae and fungus growth on them.

-The adhesive used for joining should be compatible with the surface paintwork.

Checks For Quality Work

-A sound base with no loose or peeling paintwork and no hollowness from plastering works are required.

-The base must not be porous or of excessive wetness and the base must be clean and free from dust during fixing.

-There should be no holes or scratches on them.

-The joints for cornices and beadings must have the same matching and coinciding patterns. (Fig. 3)

Fig. 3 Corner joints for cornices installed with matching and coinciding patterns.

-There should be no projection of adhesive at the joints and edges of the decorative fittings.

-Their edges must be well trimmed and pointed.

-There should be no paint drops on them.